info@idmtest.com · T. (+34) 943 571 670

info@idmtest.com · T. (+34) 943 571 670

01 february 2023

I have 3 main functions:

A- Definition of a new aesthetic line for IDM equipment.

B- Mechanical redesign of equipment already in our catalogue, with the aim of improving reliability, implementing new functions, reducing costs or reducing assembly times.

C- Design of new equipment from scratch, to expand our catalogue.

No doubt about it. But I qualify: The number one goal is to produce equipment that works as the customer expects it to. Accurate, reliable and easy to use. At IDM test we already meet all these requirements, thanks to equipment that has a highly optimised mechanical and electronic design, our own software and technology at the forefront of our sector. But when it comes to reaching the market, it is necessary that those who are going to buy our machines, when they see them, perceive all of the above.

The way to achieve this is an exterior at the same level as the interior. I believe that with the aesthetic redesign we are carrying out, we are making our equipment reflect the quality and reliability it has.

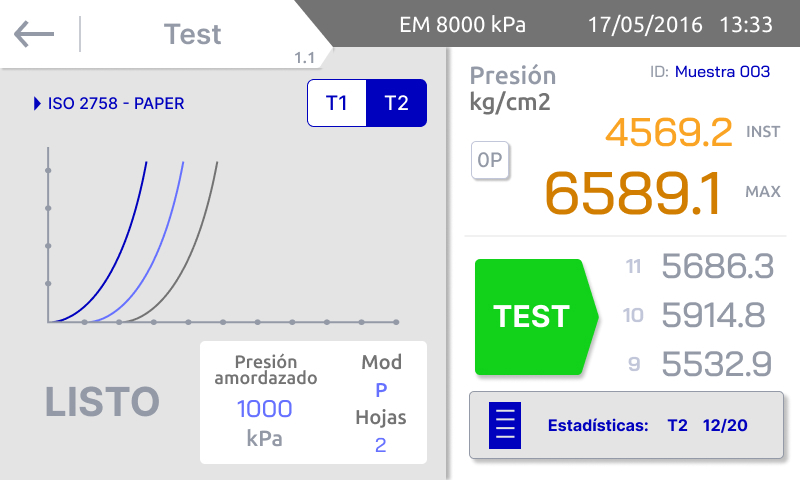

In this case, in my opinion, the aim is to look for an interface as similar as possible to the one we are all used to using, that of mobile phones. In this aspect, I consider that it is important not to try to invent the wheel and I seek to create a navigation system as similar as possible to that of today's apps. A navigation logic of this type makes it familiar to any user and makes them feel comfortable and at ease when using our devices. At the design level, it is necessary to know some theory, to prioritise the content of the interfaces, to use colours that contrast correctly to facilitate reading at first sight and to respect the minimum font size and clickable elements.

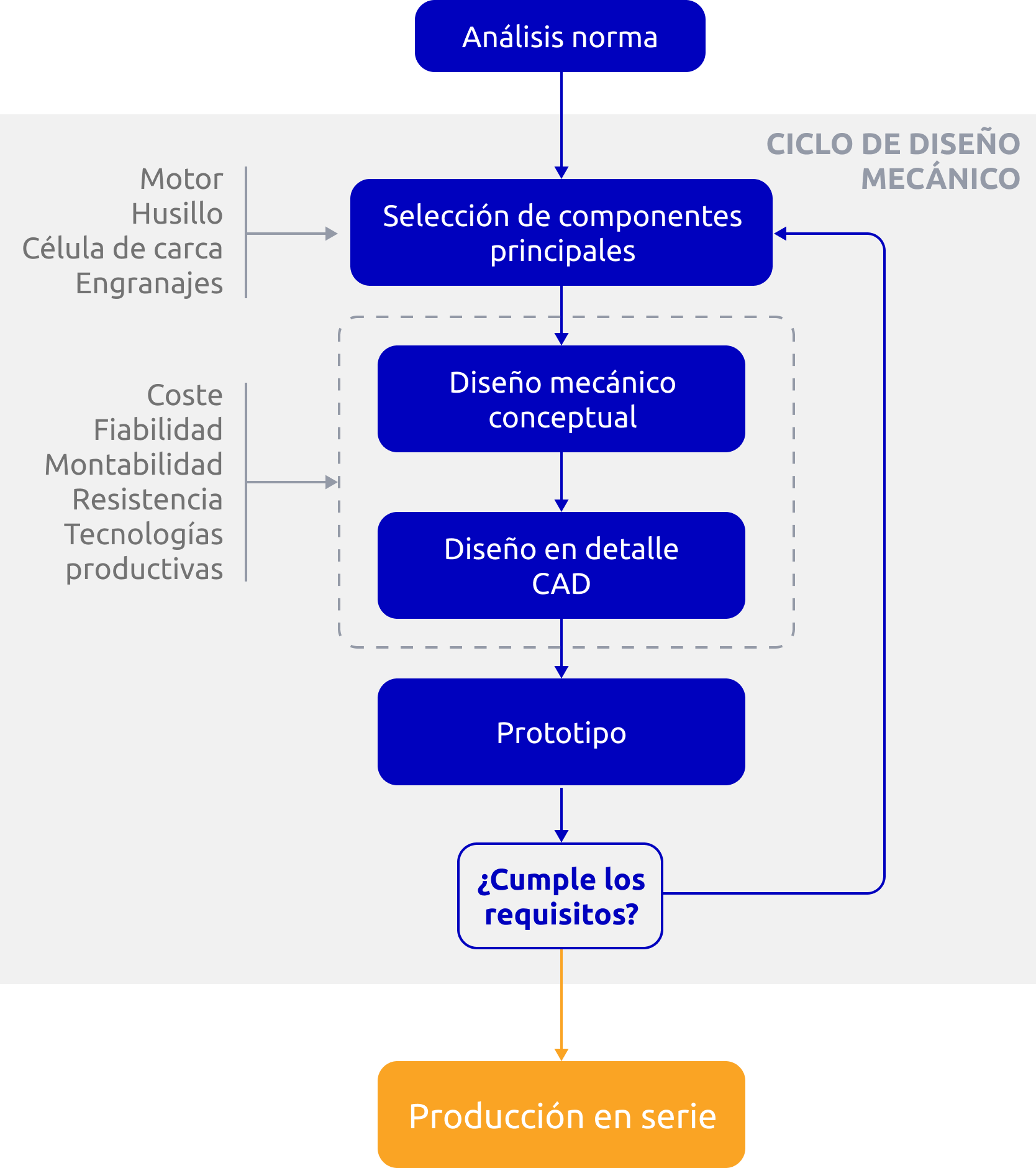

I couldn't tell you which is the most difficult, really. But of course choosing the right components is vital. A bad selection would be the equivalent of going out to play a basketball game with 3 players. We may play fabulously, but we will rarely win.

In this aspect (as in almost all) Juanjo is the reference, in the vast ocean of engineering components that exist, he is the one who has the knowledge to manage and find the most suitable ones. He has a library in the back of his head and when he looks at the ceiling it's as if he's passing bookshelves.